Por Dietmar Hoemberg (Institut für Mathematik - Technische Universität Berlin).

Abstract: Induction hardening is a modern method for the heat treatment of steel parts. A well directed heating by electromagnetic waves and subsequent quenching of the workpiece increases the hardness of the surface layer. The process is very fast and energy efficient and plays an important role in modern manufacturing facilities in many industrial application areas. Although the original process is quite old, recent years have seen an important progress due to a new technology which allows to work simultaneously with several frequencies in one induction coil.

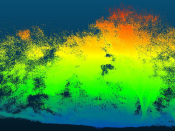

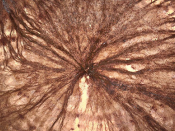

In the first part of my talk, a model for multifrequency induction hardening of steel parts is presented. It consists of a system of partial differential equations including Maxwell's equations and the heat equation. We show that the coupled system admits a unique weak solution. In the second part of the talk I will discuss the numerical approximation of the problem. It turns out to be quite intricate since one has to cope with different time scales for heat diffusion and the Maxwell system. Moreover, owing to the skin effect only the boundary layers of the component are heated by induced eddy currents, hence we also have to consider different spatial scales. We present a numerical algorithm based on adaptive edge-finite elements for the Maxwell system, which allows to treat these difficulties. We show some 3D simulations and conclude with results of an experimental validation in an industrial setting.

This seminar is supported by National Funding from FCT - Fundação para a Ciência e a Tecnologia, under the project: UID/MAT/04561/2013.