Vítor Geraldes

CEFEMA, IST, Universidade de Lisboa

Expensive biopharmaceutical drug substances are often frozen to maintain their stability and quality during long periods of time. This operation makes possible to decouple bulk solution manufacture and storage steps from final product manufacture, strongly reducing overall production costs. There are, however, multiple challenges that must be addressed to improve the reliability of the freeze and thaw process. In fact, freezing and thawing a biopharmaceutical product may change the chemical and physical properties of the product solution. During the freezing process, and depending on the freezing rate, the biopharmaceutical proteins may cryo-concentrate and during the storage and thawing steps, irreversibly denaturation or aggregation of the proteins may occur.

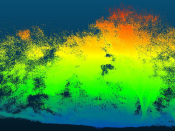

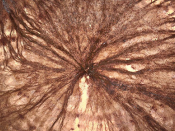

Due to the complexity of the phenomena involved in the freeze-thawing process, experimental freeze-thaw studies are required to evaluate the impact of the freezing rate and equipment geometry on the stability of the proteins. In early stage development, this becomes a challenge because material availability is limited and large-scale tests cannot be performed. It is then extremely important to develop physical scale-down models that can predict accurately the performance of large-scale equipment. Within this methodology, multi-physics simulation of freeze-thaw processes is an essential tool to support the design of scale down models, by predicting the pattern of protein cryo-concentration and thermal history of the pharmaceutical formulation, both on the small and on the large scale systems.

I will describe in this presentation a multi-physics model to simulate freeze and thawing of binary aqueous solutions. This model was developed within the OpenFOAM open source CFD toolbox. The numerical prediction of temperature profiles and cryo-concentration patterns of the solute are compared with experimental data obtained in a cylindrical vessel, using sucrose osmolyte.